Custom Direct-to-Fabric (DTF) transfers are revolutionizing apparel production by offering fast, cost-effective, and versatile solutions for creating unique designs on demand. This innovative technique enables brands to achieve superior print quality, faster production speeds, and reduced waste by eliminating complex setup and specialized equipment. DTF guarantees vibrant, durable prints on various fabrics, making it ideal for personalized hoodies, t-shirts, and more, while catering to both established brands and startups looking for flexible customization without high costs.

“Revolutionize your apparel branding with Custom Ready-to-Press DTF Transfers. This cutting-edge technology, Direct-to-Fabric (DTF) printing, offers unparalleled advantages over traditional methods. From vibrant colors to detailed designs, DTF transfers enhance product customization and brand identity.

This article demystifies the process, guiding you through designing, producing, and implementing these transfers. Learn how apparel brands are leveraging DTF technology for efficient production, exceptional quality, and distinctive branding. Discover the steps, materials, and best practices to unlock your brand’s potential with Custom Ready-to-Press DTF Transfers.”

- Understanding Custom DTF Transfers: Benefits for Apparel Brands

- – Definition and explanation of DTF (Direct-to-Fabric) transfers

- – Advantages of custom DTF transfers over traditional printing methods

Understanding Custom DTF Transfers: Benefits for Apparel Brands

Custom DTF (Direct to Fabric) transfers are a game-changer for apparel brands looking to streamline their production process and offer unique, high-quality designs on demand. Unlike traditional printing methods that require intricate setup and long turnaround times, DTF transfers are ready to press, making them an efficient and cost-effective solution. This innovative technique allows brands to easily incorporate custom artwork onto various fabric types, from cotton t-shirts to synthetic blends.

By adopting Custom DTF Transfers Ready To Press, apparel brands can benefit from faster production speeds, reduced waste, and superior print quality. The direct application of the transfer ensures vibrant colors and crisp details, making each piece a testament to the brand’s creativity. Moreover, DTF printing for t-shirts offers versatility, enabling brands to cater to diverse customer preferences while maintaining consistency in their product offerings.

– Definition and explanation of DTF (Direct-to-Fabric) transfers

Direct-to-Fabric (DTF) transfers are a cutting-edge technology in the apparel industry, revolutionizing the way custom designs are applied to fabrics. This innovative process allows for precise printing directly onto fabric surfaces, offering a seamless and efficient alternative to traditional methods. With DTF transfers, brands can achieve high-quality, vibrant prints on a variety of materials without the need for complex setup or specialized equipment.

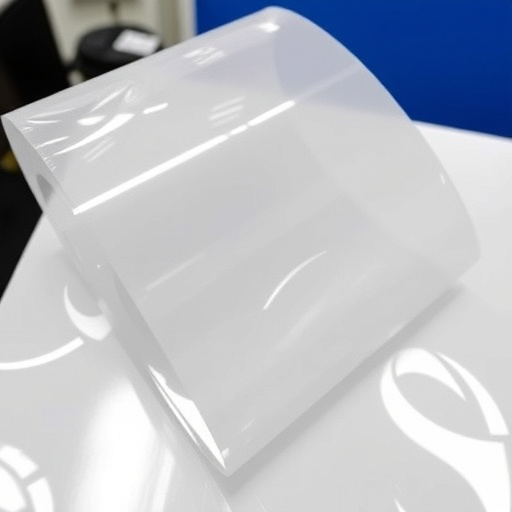

The process involves using special ink and custom sheets that are pressed against the fabric, transferring the design with precision and clarity. This method is particularly advantageous for dark fabrics, where traditional printing techniques might struggle to produce vivid colors. It provides apparel brands with a versatile tool to create unique, on-demand designs, ensuring a swift turnaround from concept to finished garment. The best DTF printers are designed to deliver exceptional results, catering to the growing demand for custom DTF transfers ready to press.

– Advantages of custom DTF transfers over traditional printing methods

Custom DTF (Direct to Film) transfers offer a multitude of advantages over traditional printing methods for apparel brands. One of the key benefits is speed and efficiency. With DTF, designs can be easily personalized and transferred directly onto fabric using a high-quality printer and specialized film. This process eliminates the need for intricate set-up and plate preparation, resulting in faster turnaround times and enabling brands to meet rapid demand, especially during peak seasons or flash sales.

Additionally, DTF transfers provide superior print quality, ensuring vibrant colors and crisp details that are lasting on various garment types. The direct application of ink onto the fabric allows for a seamless finish, making it ideal for creating personalized hoodies, t-shirts, and other apparel items with intricate designs. Moreover, this method is cost-effective, especially for small to medium-sized batches, as it requires less setup and waste compared to traditional screen printing, thus appealing to both established brands and startups looking for flexible and efficient customization options.

Custom DTF transfers ready to press offer apparel brands an efficient, cost-effective, and versatile solution for their printing needs. By leveraging direct-to-fabric technology, these transfers ensure high-quality, vibrant designs with fast turnaround times. Compared to traditional methods, custom DTF transfers provide greater flexibility in design customization and smaller minimum order quantities, making them ideal for small businesses and limited-edition collections. Embracing this modern printing technique allows apparel brands to stay competitive, cater to diverse consumer demands, and enhance their overall production workflow.