Custom DTF Transfers (Direct to Film) and Ready to Press technologies have transformed apparel production by enabling high-quality, vibrant prints on various materials, particularly custom graphic tees. This method offers excellent color accuracy, quick turnaround times, versatility, cost-effectiveness, and adaptability to trends and unique customer requests, suitable for small batches or one-off orders. Key steps include using high-resolution images (300 DPI or higher), accurate color matching, testing on fabric samples, and selecting a reliable DTF printer. Custom DTF Transfers streamline printing, eliminating complex cutting and weeding, significantly reducing production time while maintaining vibrant results, catering to diverse customer preferences, and boosting productivity for businesses of all sizes.

Discover the game-changing potential of Ready to Press DTF (Direct to Fabric) transfers for maximizing output in your custom printing projects. This article explores the benefits of DTF technology, guiding you through preparing designs optimized for press and unlocking efficiency with pre-prepared, ready-to-use transfers. Learn best practices for achieving vibrant, durable results while streamlining your workflow with these innovative solutions.

- Understanding DTF Transfers and Their Benefits

- Preparing Your Designs for Press: Tips and Best Practices

- Unlocking Efficiency: Streamlining the Process with Ready-to-Press DTF Transfers

Understanding DTF Transfers and Their Benefits

DTF (Direct to Film) transfers are a cutting-edge printing technology that has revolutionized the custom apparel industry. This innovative method allows designers and businesses to create high-quality, vibrant prints directly on transfer film, ready for application onto various materials, particularly Custom graphic tees. By using specialized equipment and inks, DTF Printing offers an efficient and precise way to produce intricate designs with excellent color accuracy.

One of the key advantages of Ready to Press DTF Transfers is their versatility. They enable quick turnaround times, making them ideal for small-batch production or even one-off custom orders. The benefits extend to cost-effectiveness, as the process reduces waste and the need for complex setup, unlike traditional printing methods. With Custom DTF Transfers, businesses can easily adapt to market trends, accommodate unique customer requests, and deliver exceptional, personalized products.

Preparing Your Designs for Press: Tips and Best Practices

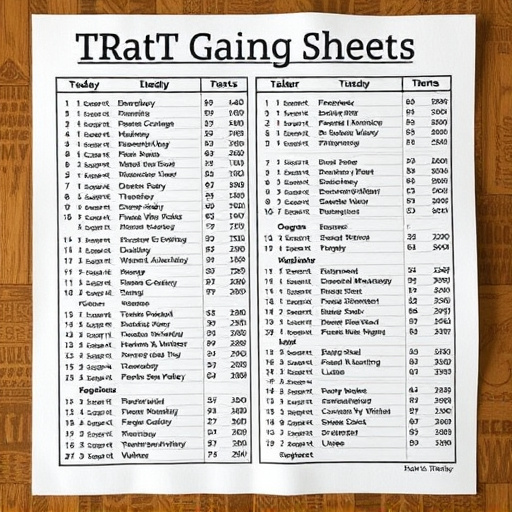

To maximize the potential of your custom DTF Transfers, preparing your designs for press is a crucial step. Start by ensuring your designs are high-resolution images with a minimum resolution of 300 DPI (dots per inch). This guarantees sharp and crisp prints on various fabrics. Next, check for color accuracy; use a color profile or software that matches the printer’s specifications to avoid off-colors in the final product.

When preparing your logos DTF for clothing brands or other applications, consider the fabric type. Different materials have unique properties; cotton, for instance, may require specific settings compared to polyester. Test your prints on samples of each fabric type you plan to use with your DTF transfer film. This ensures optimal results and minimizes wastage. Choose a reliable best DTF printer that aligns with your production needs, offering consistent quality and efficiency.

Unlocking Efficiency: Streamlining the Process with Ready-to-Press DTF Transfers

Unlocking Efficiency: Streamlining the Process with Ready-to-Press DTF Transfers

In today’s fast-paced world, maximizing output while maintaining quality is paramount for businesses in the apparel industry. Custom DTF (Direct to Fabric) transfers have emerged as a game-changer, offering an efficient and precise method of applying designs onto garments. By eliminating the need for intricate cutting and weeding processes, Ready-to-Press DTF transfers streamline the entire workflow, enabling faster production times and improved accuracy.

This innovative approach leverages advanced printing technology to produce high-resolution, vibrant designs that are perfectly aligned with the fabric. With custom sheets designed specifically for heat pressing, businesses can effortlessly incorporate unique and intricate patterns onto a variety of materials, enhancing their product offerings and catering to diverse customer preferences. Moreover, the best DTF printers on the market ensure consistent quality, making it an ideal solution for both small-scale entrepreneurs and large-volume manufacturers looking to boost their productivity.

Ready-to-press DTF transfers offer a game-changing solution for maximizing output and streamlining your printing process. By leveraging these custom DTF transfers, you can unlock unprecedented efficiency, ensuring your designs are perfectly aligned and ready for production. Say goodbye to tedious preparation and embrace a simplified workflow that enhances accuracy and productivity. With ready-to-press DTF transfers, your journey towards exceptional print outcomes is just a press away.