Custom DTF Transfers Ready to Press face common challenges like misalignments, improper file formatting and inadequate film preparation, leading to uneven design application and pixelation. Meticulous attention to detail, accurate file resolutions, color profiles, direct-to-film printing, and structured troubleshooting are essential for minimizing issues. Best practices include optimizing design software settings, using high-quality materials, calibrating equipment, pre-testing on scrap materials, and consulting manufacturer guidelines or industry experts when problems persist.

Are you an expert printer facing glitches with your custom DTF (Direct to Forme) transfers ready for press? This comprehensive guide is your savior. We demystify common issues, from file formatting to print quality problems, offering a step-by-step diagnostic approach. Learn effective solutions and best practices to ensure flawless results. Master the art of troubleshooting DTF transfers, and take your printing game to the next level with consistent, high-quality outcomes.

- Understanding Common Issues with Custom DTF Transfers

- Diagnostic Steps for Troubleshooting Press Problems

- Effective Solutions and Best Practices for Seamless Printing

Understanding Common Issues with Custom DTF Transfers

When working with Custom DTF Transfers Ready to Press, several common issues can arise that disrupt the printing process. These problems often stem from misalignments, improper file formatting, or inadequate preparation of the transfer film. For instance, misalignment between the design and the garment during heat pressing can result in uneven application of the design, affecting the final quality of the product.

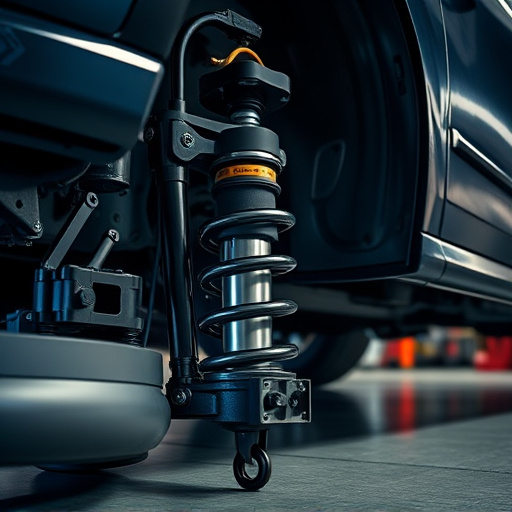

Moreover, using custom sheets for heat pressing designs onto garments requires meticulous attention to detail. Inaccurate file resolutions or incorrect color profiles can lead to pixelation or distortion in the printed image. A direct to film printer is essential for ensuring accurate and vibrant DTF printing for t-shirts and other textiles. Proper setup and calibration of these printers are crucial to minimizing issues related to color accuracy, registration, and overall print quality.

Diagnostic Steps for Troubleshooting Press Problems

When encountering issues with Custom DTF Transfers Ready to Press, a systematic approach through diagnostic steps is essential for effective troubleshooting. Start by inspecting the DTF transfer sheets for any visible damage or contamination. Ensure proper alignment and pressure during the press setup, as misalignment can lead to poor transfers. Check the condition of your press components, especially the platens and inking mechanisms, for wear or malfunction.

Next, verify the quality of the design file and its compatibility with the transfer process. Inaccurate or poorly resolved designs might cause issues. Test the ink and substrate combination to ensure optimal adhesion and color accuracy. Monitor the printing speed and temperature settings; deviations from recommended specifications can result in transfer failures. Lastly, consult the manufacturer’s guidelines and seek support from industry experts for persistent problems, leveraging their experience with DTF transfers to resolve complex issues effectively.

Effective Solutions and Best Practices for Seamless Printing

Ensuring seamless printing with Custom DTF Transfers Ready to Press involves adopting best practices that streamline the process and deliver exceptional results. One effective solution is to optimize your design software settings, ensuring proper resolution and color profiles for accurate reproduction on various fabrics, especially when creating DTF for Apparel, like custom graphic tees. This attention to detail minimizes imperfections and ensures vibrant, long-lasting prints.

Additionally, investing in high-quality transfer paper and printers specifically designed for DTF printing for t-shirts is paramount. Regularly calibrating your equipment and using premium inks compatible with your printer model can significantly reduce issues. Pre-testing on scrap materials before full production runs allows for identifying potential problems early on, enabling prompt adjustments to achieve perfect DTF for Custom graphic tees.

When troubleshooting custom DTF transfers ready to press, understanding common issues and taking proactive steps can significantly enhance your printing experience. By following diagnostic procedures and implementing effective solutions, you can ensure seamless results for your custom DTF transfers. Remember that meticulous attention to detail and adherence to best practices are key to achieving vibrant, high-quality prints every time.