Custom DTF (Direct-To-Fabric) transfers revolutionize print-on-demand production by enabling designers to create vibrant, unique designs on light fabrics like t-shirts and hats. This efficient process starts with optimizing artwork and ends with high-quality prints, offering a simple setup and cost-effective solution for businesses to meet demand for custom, fashion-forward items. Ready-to-press transfers streamline production, reduce waste, and provide extensive design flexibility, making DTF ideal for small batches or single-item customization.

“Revolutionize your Print-on-Demand store with Custom Ready to Press Transfers (RTPT). This article delves into the world of Direct-to-Transfer (DTF) printing, offering a compelling solution for businesses seeking quality and efficiency. We’ll explore the basics of DTF, its advantages, and popular materials. Learn about design considerations, recommended software, and sourcing high-quality transfers. Additionally, discover how to seamlessly integrate RTPT into your workflow, optimize storage, and implement best practices for exceptional print results.”

- Understanding Custom DTF Transfers: The Basics

- – Definition and explanation of Direct-to-Transfer (DTF) printing

- – Benefits for print-on-demand businesses

Understanding Custom DTF Transfers: The Basics

Custom DTF (Direct-To-Fabric) transfers are an innovative way to create unique designs for print-on-demand stores. These ready-to-press transfers offer a straightforward and efficient process for applying artwork directly onto various fabrics, from t-shirts to hats and more. The technology behind DTF involves using heat-sensitive ink that, when combined with specialized printing equipment and a heat press, permanently adheres the design to the fabric.

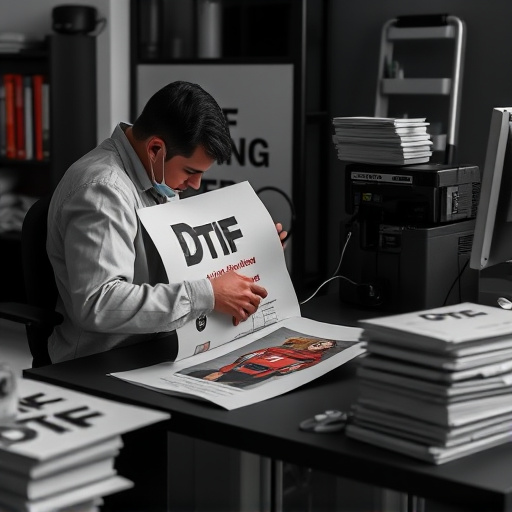

This method is particularly advantageous for print-on-demand businesses as it allows for quick turnaround times and easy customization. With custom DTF transfers, designers and store owners can create on-trend, personalized products without the need for complex setup or expensive machinery. The process begins with preparing the artwork, ensuring it’s optimized for DTF printing. Then, the design is printed onto a special transfer paper using solvent ink, which becomes temporarily attached during the heat press cycle, eventually fusing into the fabric. This technique results in vibrant, long-lasting prints on light fabrics, making it ideal for creating demand-driven, fashion-forward items.

– Definition and explanation of Direct-to-Transfer (DTF) printing

Direct-to-Transfer (DTF) printing is a cutting-edge technology revolutionizing the print-on-demand industry. It’s a process that allows for direct application of digital images onto various surfaces, most commonly t-shirts and other textiles. In this method, custom designs or graphics are precisely printed onto special transfer films using high-resolution inkjet printers. These transfer films act as intermediates, carrying the design until they’re pressed onto the desired material, typically during the heat press process.

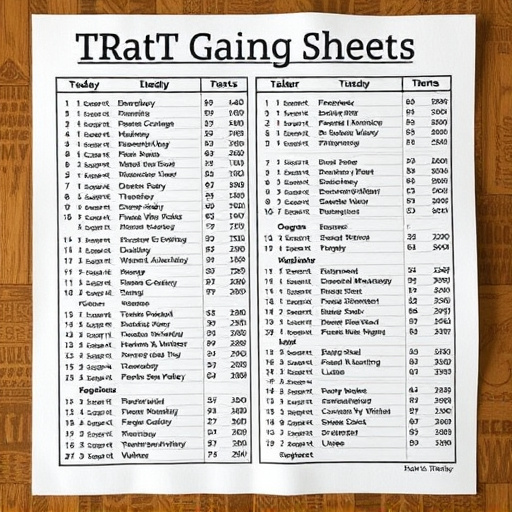

DTF offers numerous advantages for print-on-demand stores. It enables businesses to create custom DTF transfers ready to press, streamlining production and ensuring top-quality prints. This technology supports a wide range of DTG for t-shirts, from vibrant graphics to intricate designs, all while maintaining exceptional detail and color accuracy. Moreover, it’s an efficient method for small batch production or even single-item customization, making it versatile for various print-on-demand applications.

– Benefits for print-on-demand businesses

Print-on-demand businesses can greatly benefit from adopting custom ready-to-press transfers, such as DTF (Direct to Fabric) Transfers. These innovative tools streamline the production process, enabling efficient and cost-effective creation of Custom graphic tees and other clothing items. By using DTF for Custom graphic tees, stores can significantly reduce setup times and minimize waste, making bulk dtf shirt production both economical and eco-friendly.

With ready-to-press transfers, businesses gain unparalleled flexibility in their design offerings. They can quickly adapt to changing market trends, customer demands, or seasonal fluctuations by easily creating and updating custom designs. This agility allows print-on-demand stores to stay competitive and cater to a wide range of consumer preferences, ultimately driving sales and fostering growth.

Custom DTF transfers ready to press are a game-changer for print-on-demand stores, offering efficient production and versatile design possibilities. By streamlining the printing process, these transfers enable businesses to cater to diverse customer demands swiftly and cost-effectively. With their advanced technology and customizable options, they represent an indispensable tool for modern, agile printing operations.